This guide to international logistics was written for ICC Academy by Louise Wiggett and Helen Scrimgeour from Global Trade Solution (GTS). GTS provide consulting services to the international trade and supply chain community. The views expressed in this article do not necessarily represent the views of ICC or the ICC Academy.

What is international logistics?

International logistics involves planning, implementing and overseeing the effective storage and transportation of goods through an international supply chain.

While the terms “logistics” and “supply Chain” are sometimes used interchangeably, it is important to understand that logistics is an element of the overall supply chain. Each of these make up a separate part of the commercial process.

Logistics refers to the movement of goods from one point to another. Two distinct functions are involved; namely transportation and warehousing.

The overall supply chain is a network of stakeholders working in a sequence of processes, including international logistics, to produce and distribute goods.

Logistics is also concerned with optimising every process along the supply chain to lower prices, improve services, and boost profits.

Without logistics, supply chains would descend into chaos. Logistics ensures that merchandise arrives in the right place at the right time and streamlines every step along the way.

The main objective of international logistics is the efficient and cost-effective delivery of goods to consumers in a global marketplace within the agreed timelines.

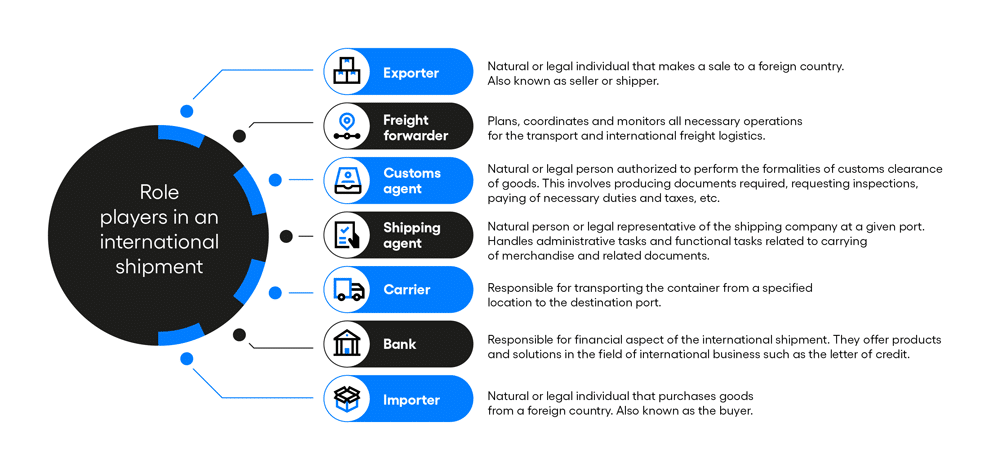

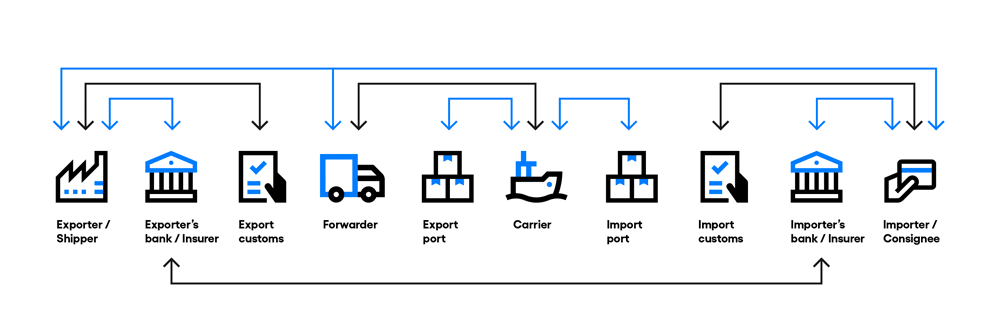

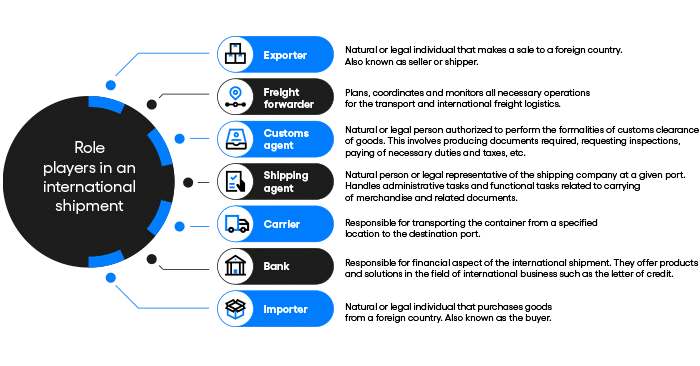

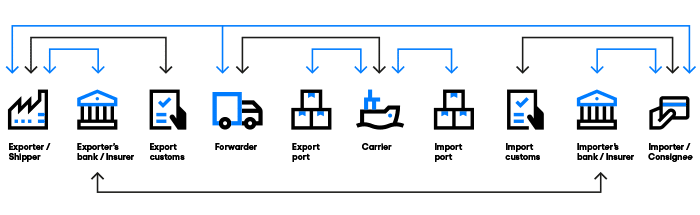

Who does international logistics involve?

Many people and functions play a role in the international supply chain. The graphic below summarises the key stakeholders and their role in the international trade transaction.

Click image to enlarge

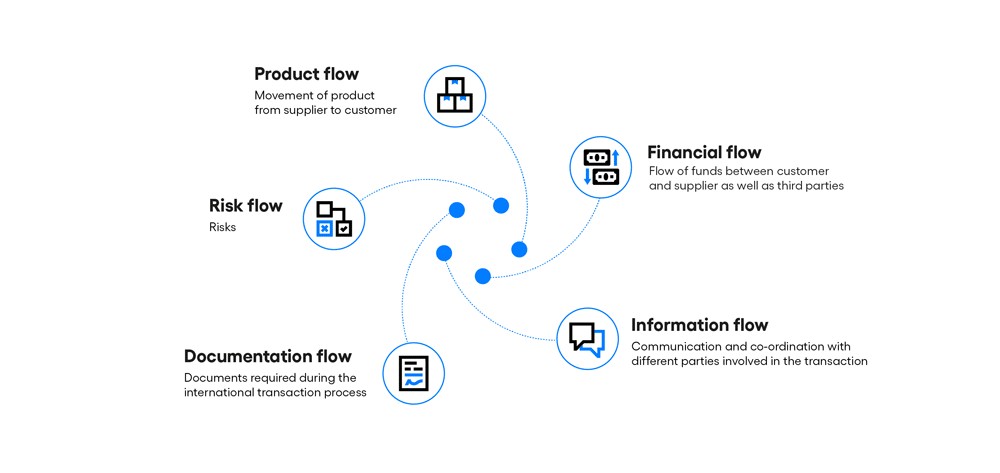

International supply chain flow

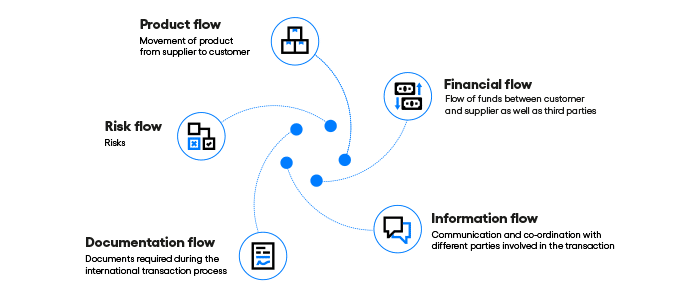

As mentioned international logistics is one element of a supply chain. To better understand logistics and where it fits in, it is also important to understand the other flows and activities that are involved in an international supply chain.

Click image to enlarge

Product flow

Product flow describes the movement of physical goods from a supplier all the way to the customer.

The process starts with raw materials, which are then transported to a manufacturer who creates a finished product. From here, the manufacturer will send the goods to a warehouse or other kind of storage facility, and goods then move into the distribution channels for delivery to the end customer.

The flow of goods is usually one-directional; however, there are exceptions to this, for instance where goods are returned.

Financial flow

The product flow is supported by the financial flow, whereby money moves along the supply chain from the customer to the supplier. The financial flow is facilitated through payment terms and payment documents.

This flow is typically one-directional, but sometimes the finances flow from supplier to customer in the form of a debit.

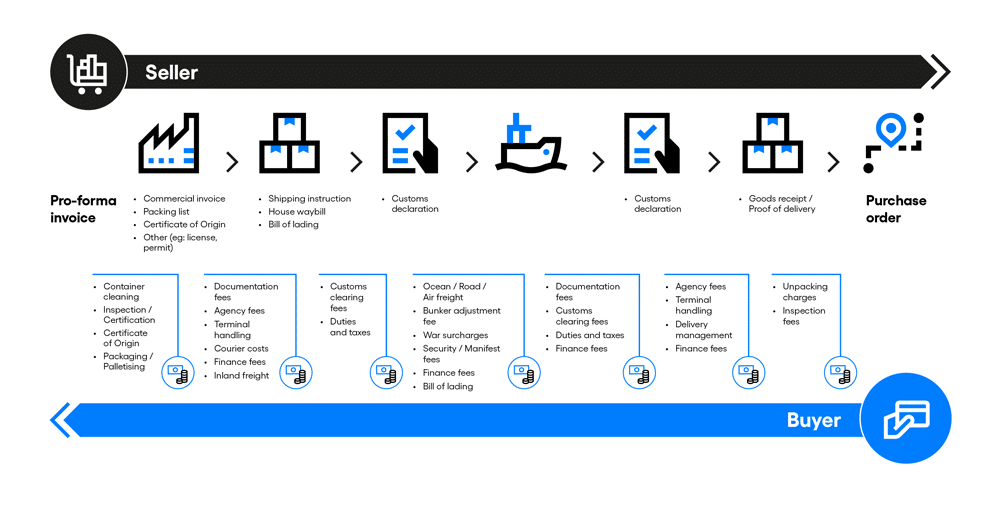

Click image to enlarge

Information flow

Information flow is critical in all supply chains. The flow of information supports the movement of products and money and is essential to enable planning and execution of key actions in the supply chain.

Information flow is multi-directional and flows between suppliers and customers in either direction as well as between other stakeholders in the trade transaction.

Each participant in the supply chain needs relevant information to make effective forecasts and operational decisions. This information needs to be accessible, relevant, accurate, timely, and transferable.

Supply chain information technologies support timely, cost-efficient sharing of information between suppliers, manufacturers, intermediaries, logistics services providers, and customers.

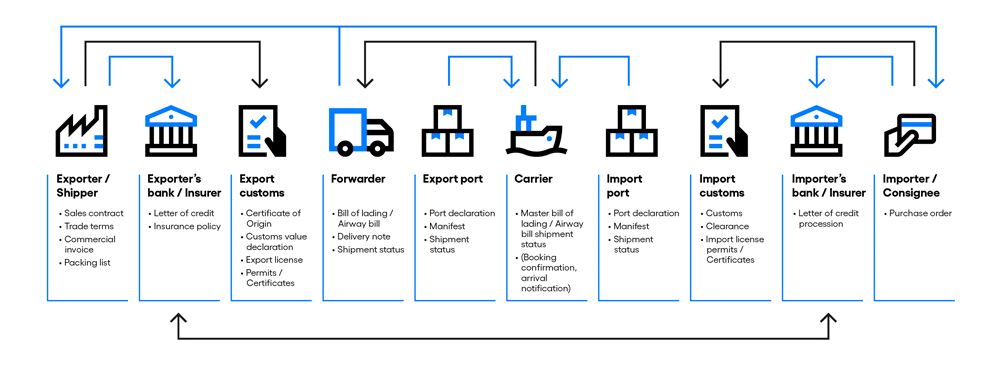

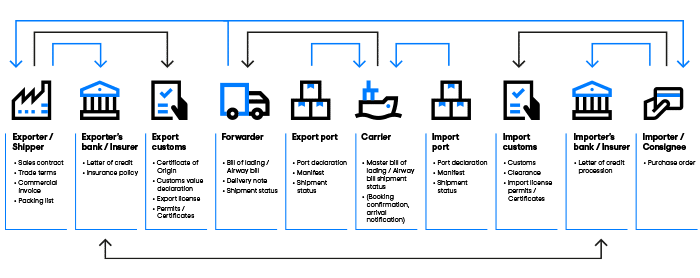

The graphic below illustrates the flow of information in a supply chain, and the key stakeholders involved.

Click image to enlarge

Documentation flow

Tracking of documentation within the supply chain is critical to the flow of information and goods. There are many types of documentation that are required for the movement of goods, and all of these play a specific role within the trade transaction.

Keeping track of the various documents can be complex and time-consuming. However, the process can be made easier by supply chain management software, which facilitates the creation, flow and accessibility of important documents, and enables visibility amongst stakeholders.

Some examples of documents that are required in international trade are:

- Pro forma invoice

- Commercial invoice

- Packing list

- Customs declaration

- Manifest

- Freight bill

- Bill of lading

- Terms of sale

- Insurance certificate

- Certificate of origin

- Export licences

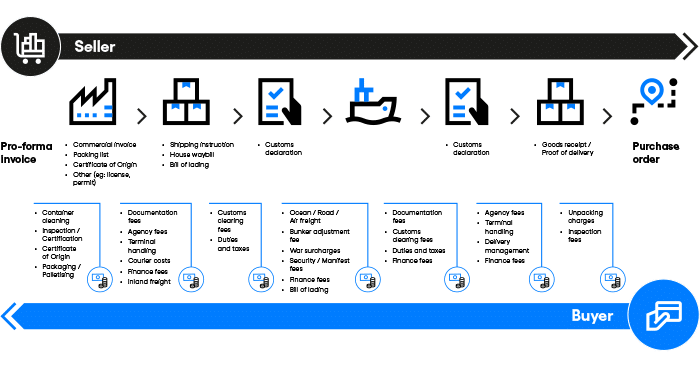

The graphic below illustrates the flow of documents in a supply chain, and the key stakeholders involved.

Click image to enlarge

Risk flow

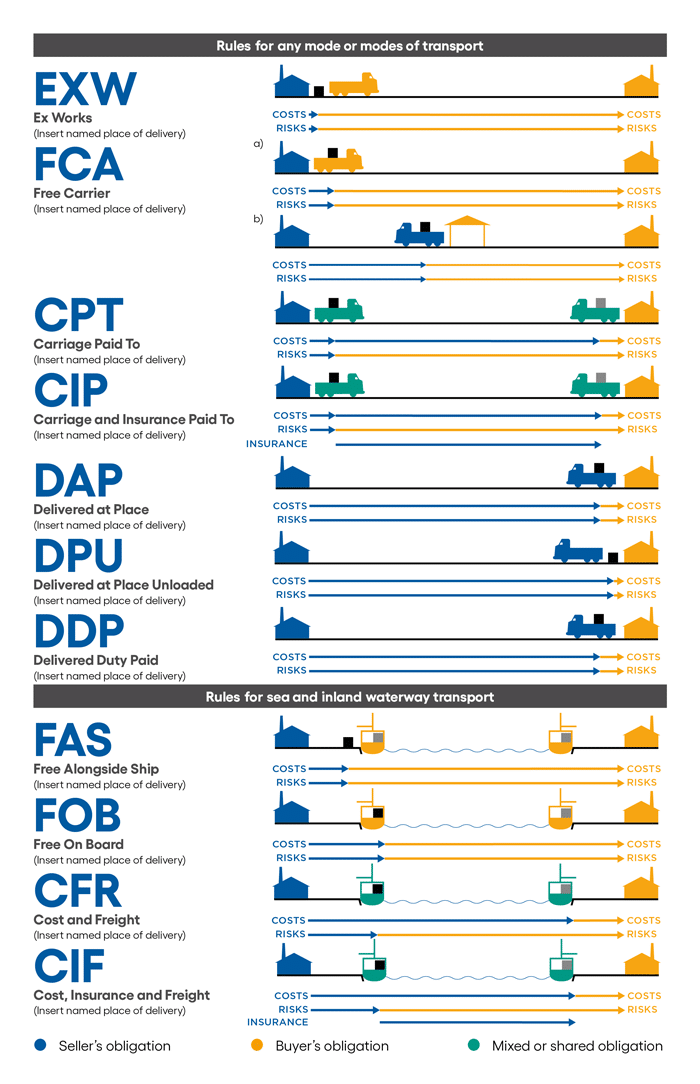

The flow or transfer of risk of loss or damage to goods is an important concept in the supply chain. ICC's Incoterms® 2020 rules (International Commercial Terms) state when the seller’s costs and risks are transferred onto the buyer.

Why international logistics is so crucial to supply chains

Without international logistics, international trade would not be possible.

The international logistics process involves the shipping and fulfilment of finished goods through a global supply chain network. Furthermore, it consists of international transportation and distribution for efficiently delivering goods to end-users across the globe.

With the on-going expansion of international trade and with supply chains crossing multiple borders, countries need to ensure that their transport, logistics, connectivity and trade-related infrastructure is adequate to support these increasingly complex networks.

Logistics is one of the most critical factors in the efficiency of a supply chain. Without a properly designed transportation flow, the supply chain cannot ensure high value. The implementation of seamless international logistics becomes a key element in meeting customer demands and remaining competitive.

Effective logistics improves the supply chain by minimising waste of both time and materials. A well-designed logistics network may appear effortless but requires specialist knowledge and skills to achieve a smooth flow.

Benefits of effective international logistics

Business growth

As businesses grow both regionally and internationally, their dependence on effective logistics increases. No matter the business location or industry, logistics can help with improved efficiency in movement of goods, cutting costs and increasing profitability.

International market opportunities

By working with international logistics centres and using global freight services, global logistics mean more market opportunities. Although there are some differences in consumers’ habits from country to country, most eCommerce businesses can sell their products worldwide with small alterations to the products or no changes at all.

Cost reduction

Moving stages of the supply chain to other countries can be a financial advantage. Sometimes a resource is not available locally or is cheaper when sourced internationally. Relocating production activities to a more cost-effective location is common practice, enabling companies to invest in other areas, such as innovative technologies.

International logistics is the backbone which makes these international sourcing and production strategies possible.

Value to customers

Logistics creates and increases the value that businesses offer by ensuring the availability of products. To provide more value, businesses either work on improving their own logistics activities or rely on professionals. Better logistics makes products more available to a wider group of people.

Efficient product delivery

In today’s fast-paced marketplace, delivery time expectations are becoming shorter. Logistics is essential to maintaining distribution networks and the timely and safe transportation of goods to meet customer demand.

The different components of international logistics

Handling of goods

Due care needs to be taken to ensure that goods are not damaged or are otherwise compromised during their journey to the customer. Any written instructions provided by the consignor relating to the handling of goods also need to taken into account and adhered to.

Customs clearance

Foreign goods imported into a country must be processed through a customs agency or authority. It is important that customs procedures are followed correctly to avoid delays and penalties. To this end, importers may make use of the services of a customs broker to act as its agent in the clearance process.

Track and trace

Visibility of goods along the supply chain helps with planning as well as for contingency arrangements in the event of delays. Carriers typically provide some kind of track and trace functionality via an online enquiry tool, providing real-time information.

Confirmation & payment

Confirmation of receipt of goods is also an important aspect of international logistics, as this will inform the seller that the product has been received by the customer and the billing / payment process can commence.

Demand planning

To guarantee customer order fulfilment, demand planning is an essential logistics function. By ordering merchandise in the correct quantities and at the right price and mobilising suitable transport, customer demand is met and profits protected.

Storage and warehousing

The role of warehousing in the supply chain is to ensure that there is a place to store products supplied by a manufacturer, so that these are ready to ship to a customer on demand.

Manufacturers tend to supply products at a predictable and steady pace, while consumers tend to order goods in a more erratic and generally unpredictable manner. Storing surplus goods in an easily accessible warehouse ensures that consumer demand can generally be met.

Packaging and unitisation

Products are usually presented in some form of packaging, which serves as a means of identification and information as well as protection.

Unitisation involves consolidating different shapes and sizes of products to try to pack them as closely as possible into a cube shape, as this is an easy shape to move and store.

Inventory and inventory management

Inventory is a term to describe the stock of products in a warehouse, and involves understanding what stock is being held, how much, and where it is located. Inventory also controls the flow of goods into and out of the warehouse.

Inventory management attempts to predict the amount and type of goods that will be ordered by consumers and controls the movement of goods in and out of a warehouse.It is a useful tool for the flow of goods in a supply chain.

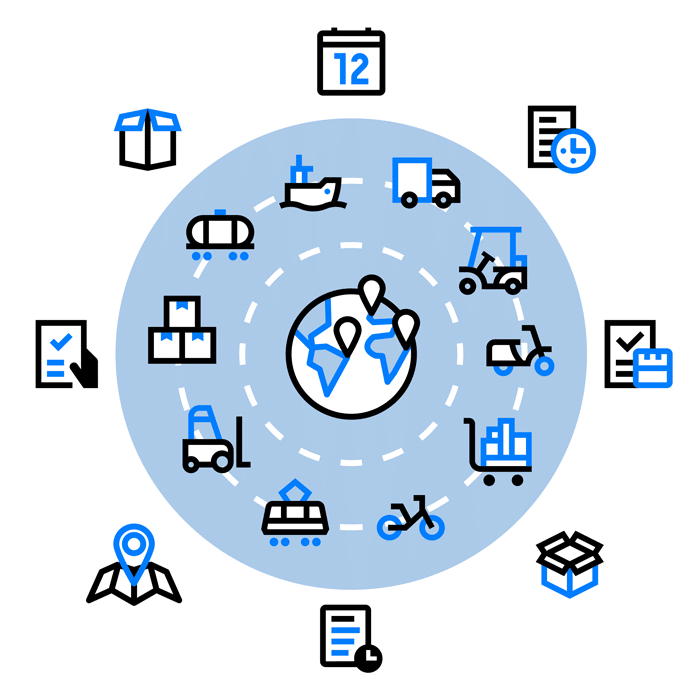

Logistics networks

Service efficiency is achieved by careful design of logistics networks, optimising routes between the different locations comprising the supply chain (such as between manufacturers, warehouses, service providers and the end consumer).

Transportation

Transportation is a key element of logistics, facilitating the movement of goods from one area of the supply chain to another. It can involve multiple modes of transport, such as trucks and other road vehicles, freight trains, containerised shipping, and aeroplanes (road, rail, sea and air).

Another aspect of transportation involves consolidation, the process by which shipping companies combine several smaller orders into one shipment, thus speeding up overall delivery times whilst controlling costs.

Information and control

International logistics is a complex operational procedure that requires a lot of precise information to be effective. Forecasting demand, transportation times, and inventory are crucial to keeping the operations to a tight timescale.

Reverse logistics

In addition to distributing products to the end customer, an important part of international logistics involves reuse or the correct disposal of products and materials. This is known as 'reverse logistics', and the process flow is in the opposite direction to handle excess or used merchandise in a sustainable manner.

Key challenges of international logistics

The world-wide response to the COVID-19 pandemic saw the implementation of a number of regulatory measures which affected global trade, with trade compliance particularly affected.

For example, countries implemented restrictions and controls around the import and export of goods to reduce the movement of cargo and people across borders, all in a measure to protect their populations from the spread of the virus.

Certain kinds of goods were also subject to new export and import controls. For example, medical supplies, face masks, hand sanitizer, etc. Over time, some of these were removed or minimised, while others remained in place.

Some examples of measures implemented in response to the pandemic:

- In an attempt to boost local business, Botswana implemented a ban on the import of face masks, encouraging local manufacturers to produce these locally.

- Exports in certain countries were controlled to ensure that a country did not run out of essential supplies.

- Namibia required that imported hand sanitizer comply with specific standards.

In addition to specific controls and measures on goods, countries also sought to enhance their digital solutions to minimise human contact.

This included making use of online platforms for management of client queries and implementing improved functionality in online customs management systems. Other measures included utilisation of non-intrusive inspection equipment.